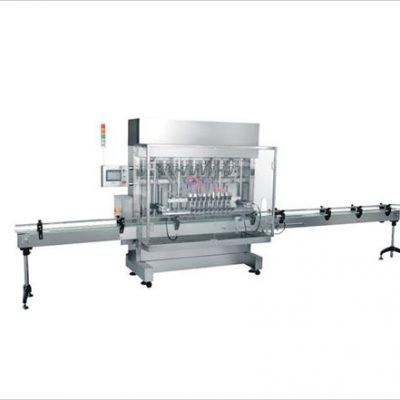

A dishwashing liquid filling machine is a type of automated equipment that is designed to fill bottles or containers with dishwashing liquid. It typically uses a series of pumps, sensors, and nozzles to accurately measure and dispense the correct amount of dishwashing liquid into each container. These machines can be used in industrial or commercial settings to increase production efficiency and accuracy.

Specifoj

lavaĵo de likva pleniga maŝino

1. With CE Certificate,Meet the GMP

2. Material:304or316Stainless Steel

3. Pay:T/T,L/C

Priskribo

CE de EU

ISO9001

Plenumu la postulojn de GMP

longlife of service, low mainteinance rate

Ĉefa funkcio

La maŝino estas progresinta alta precizeco pleniganta maŝinon, kiu povas kompletigi la botelon, nombrante, plenigante kaj kaptan procezon aŭtomate.

Trajtoj

1. Kompakta strukturita, bonaspekta, facila por funkcii kaj tre aŭtomatigita.

2. komponantoj de kontakto kun materialo estas faritaj el neoksidebla ŝtalo, facile purigeblaj.

3. Pleniga volumo estas kontrolita per filmaj valvoj por certigi precizecon.

4. Alta rapideco kaj tre precizaj plenigaj valvoj certigas neniun filtradon.

5. Ĝi estas ekipita per alt-efika ĉapo-nutra sistemo.

Lingva Eblo

Monitor language: English, Spanish, Arabic, Portuguese, Russian, Italian, French, Korean.

Gravaj trajtoj:

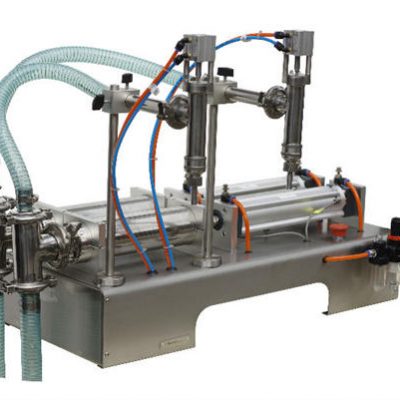

1. Linear type piston filling machine special designed for sticky liquid,such as detergent, shampoo, lotion,lubricant oil,edible oil, etc. international advanced technology, already approved by well-known companies such as Bayer. High filling accuracy, simple structure, stable working, widely application. Counting of bottles inlet, qualitative filling, bottles outlet are done automatically.

2. Not only the whole 13 filling nozzles dosage can be rough adjusted, but also each single filling nozzles dosage can finely adjusted.

3. Povas enmemorigi multajn parametrojn, helpemajn por diversaj specifoj ŝanĝitaj, ĉiu pleniga dozo povas esti ĝustigita per tuŝekrano.

4. Liquid control for normal working liquid level control, sound and light alarm device, guarantee the liquid level at normal condition; also can achieved for inlet valve/pump control.

5. Material outlet joints all adopts quick-assembling type (clamp type), easily for clean. Sealing gaskets adopts fluorine rubber O-ring; sanitary connecting pipes.

6. With protection case, drip gutter, main materials are made of SS304, wetted parts are made of SS316L.

Ĉefa teknika parametro

| Ero | Nomo | Teknika parametro |

| 01 | Maŝina dimensio (L * W * H) | 2200mm * 1400mm * 2800mm |

| 02 | Maŝina pezo | Ĉirkaŭ 1400Kg |

| 03 | Ena diametro de la ujo | ≥φ35mm |

| 04 | Taŭga ujo | 1Liter .2Liter |

| 05 | Alteca ujo | 80-350mm |

| 06 | Potenco | AK 380V; 50HZ |

| 07 | Potenco | 5Kw |

| 08 | Pleniga precizeco | ≤ ± 1% |

| 09 | Aerfonto | 0.6Mpa stabila kaj pura kunpremita aero |

| 11 | Nombro de plenigaj cigaredoj | 13 |

| 12 | Alteco de la transportilo | 900mm ± 50mm |

| 13 | kapablo | ≤3200boteloj / horo (prenu akvon kiel testo) |

| 14 | Botelo en nutra direkto | De maldekstre dekstren |

Rapidaj Detaloj

Tipo: Pleniganta Maŝino

Kondiĉo: Nova

Apliko: Kemia

Pakado Tipo: Boteloj

Paka Materialo: Ligno

Aŭtomata Grado: Aŭtomata

Kondukita Tipo: Pneŭmatiko

Tensio: 220v

Potenco: 3KW

Loko de Origino: Ŝanhajo. Ĉinio (kontinento)

Marka Nomo: VKPAK

Dimensio (L * W * H): 2200mm * 1400mm * 2800mm

Pezo: 1400

Atesto: CE

Post-venda Servo Provizita: Inĝenieroj haveblaj al serva maŝinaro eksterlande

materialo: SS304

PLC: Panasonic

Tuŝekrano: Panasonic

Dishwashing liquid filling machines are specifically designed to package dishwashing liquids into various types of containers. These machines are essential for businesses in the cleaning industry who want to streamline their packaging process and increase their productivity. There are several types of dishwashing liquid filling machines available in the market, each with its unique features and benefits.

One of the most popular types of dishwashing liquid filling machines is the volumetric filler. This machine operates on the principle of displacement and uses a piston to fill the containers with the precise amount of liquid required. This type of machine is highly accurate and is suitable for packaging liquids with a constant viscosity.

Another type of dishwashing liquid filling machine is the gravity filler. This machine works on the principle of gravity and uses a funnel to fill the containers with the liquid. The liquid is then dispensed into the containers based on the height of the liquid in the funnel. This type of machine is ideal for packaging low viscosity liquids and is very cost-effective.

The third type of dishwashing liquid filling machine is the overflow filler. This machine works on the principle of overflow and uses a hopper to fill the containers with the liquid. The liquid is then dispensed into the containers based on the height of the liquid in the hopper. This type of machine is ideal for packaging high viscosity liquids and can handle liquids with large particles.

When choosing a dishwashing liquid filling machine, it is important to consider factors such as the size of your production line, the viscosity of the liquid, the type of containers you will be using, and the speed of production you require. It is also important to consider the ease of maintenance and the reliability of the machine.

In conclusion, a dishwashing liquid filling machine is a crucial investment for businesses in the cleaning industry. With the right machine, businesses can increase their productivity, improve the quality of their packaging, and save time and money. When choosing a dishwashing liquid filling machine, it is important to consider factors such as the size of your production line, the viscosity of the liquid, the type of containers you will be using, and the speed of production you require.